Key Benefits

|

|

Tolerances

| Molds: | +/- .0001 |

| Plastic Parts: | +/- .0005 |

| Wall Thickness: | +/- .0005 |

| Cavity Depth: | 14" |

| Surface Finishes: | SPI-SPE #2 |

Maximum Mold Build

|

|

Maximum Mold Sample And Process

|

|

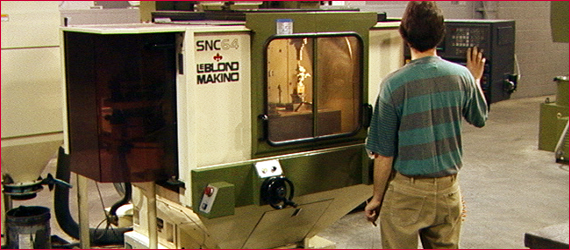

Technical Capabilities

Hot Runners As Required

Hot Runner Benefits

Faster cycles

More uniform parts and color

More uniform process control uniformity

Less regrind or scrap material

Hot runners should be used whenever financially feasible

Steel

As required by customer specifications and primarily S-7 and

A-2 in hardened tooling with P-20 in soft tooling.Steel selection is dependent on customer specifications and or useful life expectancy of the tool. Steel certifications are on file.

Expertise

|

|

Special Process

|

|

|